ForumIAS announcing GS Foundation Program for UPSC CSE 2025-26 from 19 April. Click Here for more information.

ForumIAS Answer Writing Focus Group (AWFG) for Mains 2024 commencing from 24th June 2024. The Entrance Test for the program will be held on 28th April 2024 at 9 AM. To know more about the program visit: https://forumias.com/blog/awfg2024

Contents

| For 7PM Editorial Archives click HERE → |

Introduction

The cost of green hydrogen made by electrolysis is estimated to be around ₹350 per kg and the Centre plans to bring it down to ₹160 per kg by 2029-30.

Addressing the International Climate Summit 2021 held recently, Mukesh Ambani, Chairman and Managing Director of Reliance Industries (RIL), said, “Efforts are on globally to make green hydrogen the most affordable fuel option by bringing down its cost to initially under $2 per kg. India can set an even more aggressive target of achieving under $1 per kg within a decade. This will make India the first country globally to achieve $1 per 1 kg in 1 decade – the 1-1-1 target for green hydrogen”

Achieving this target will substantially reduce the carbon footprint and have a favorable impact on the trade balance too. But the engineering problems associated with 1-1-1 are also equally formidable.

What is Green Hydrogen?

Green Hydrogen is the clean hydrogen generated by using renewable energy such as solar power and wind energy. The by-products are water and water vapor.

Green hydrogen is produced via the electrolysis of water. All you need to produce large amounts of hydrogen is water, a big electrolyzer, and large supplies of electricity. If the electricity comes from renewable sources such as wind, solar or hydro, then the hydrogen is effectively green; the only carbon emissions in its production will occur from the generation infrastructure.

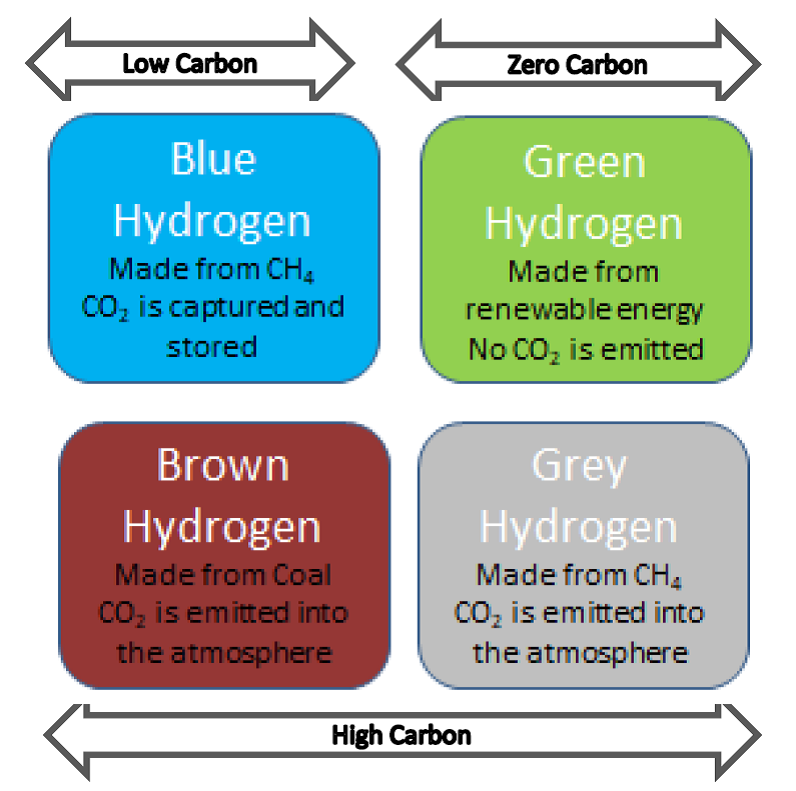

There are many types of colors associated with multiple variants of hydrogen. The following pic describes these different variations:

Why India needs green hydrogen?

Reduced energy bill: India imports over 85% of its crude oil and more than 50% of its gas. It spends around ₹12 trillion annually for its energy needs. Any savings because of reduced energy imports following the domestic increase of green hydrogen production will be a boon. The valuable foreign exchange savings can be deployed towards infrastructure creation, health, and education. It will also help India meet its nationally determined contribution targets under Paris Agreement.

Dependence on coal: It also burns domestically-mined coal and lignite to run thermal plants to generate 65% of the power.

Future energy demand: Moreover, energy demand will grow alongside the country’s gross domestic product.

Thus, green hydrogen will be a major component of renewable capacity, reducing dependence on fossil fuels and reducing India’s import bill too.

How is India positioned favorably wrt Green Hydrogen production?

Most parts of India receive 4-7 per kilowatt-hour (kWh) of solar energy per square meter per day

Thus, India’s large landmass and low wind and solar tariff can be leveraged to produce low-cost green hydrogen and ammonia for exports, thus bolstering India’s geopolitical weight.

| Must Read: National Hydrogen Energy Mission |

What are the advantages of Hydrogen?

As per CEEW analysis, the total investment potential of green hydrogen in India is $44 billion by 2030. Further, green hydrogen holds the potential to become competitive for end-use sectors like steel and ammonia within the next decade.

Low-carbon footprint: Hydrogen is the most abundant element and is easily harvested by running a current through the water in a process called electrolysis. When hydrogen recombines with oxygen, it generates power with emissions of water. If electrolysis is done with renewable energy, the entire cycle is very low-carbon with less environmental impact than solar or wind.

Less capital imports: It may require less capital equipment imports, to create green hydrogen capacity.

Good storage material: Apart from use in transportation, hydrogen may be a good storage material for surplus electricity generated from renewables. Solar and wind are intermittent; sometimes they don’t generate any power, and sometimes they generate a surplus. The surplus can be used to electrolyse hydrogen, which can be stored.

Higher energy value: Weight for weight, 1 kg of hydrogen has roughly thrice the energy value of 1 kg of diesel.

What are the potential challenges?

Highly reactive: Hydrogen is highly reactive at room temperature. So, storage and distribution require either high compression to store in special tanks, or chilling to below minus 250oC to liquefy. It takes up a lot of space too. 1 kg of Hydrogen, occupies a volume of about 11,000 litres, versus just over a litre per kg of diesel.

Dedicated infrastructure: It has a habit of making steel pipes and welds, brittle and prone to failure. Hence, the bulk transport of hydrogen will require dedicated pipelines, which would be costly to build, pressurizing the gas, or cooling it to a liquid.

Pressure on land: After converting electricity to hydrogen, shipping it, storing it, and then converting back to electricity, the delivered energy can be below 30 per cent of what was the initial electricity input. Hence, we need huge amounts of electricity from renewable sources which is going to put pressure on land.

Cost is an issue: Producing green hydrogen costs between $3.5/kg and $6.5/kg, depending on the cost of power. Cutting this, first to $2 and then to $1, will require new technologies and scale.

Storage and transport issues: While hydrogen has a very high energy content per unit of mass compared to natural gas, its energy density is low per unit of volume. Hence, we need huge containers to transport hydrogen. It’s possible to convert hydrogen to liquid form to facilitate transportation. But it has to be cooled to minus 253 degrees Celsius and then reconverted which would require a lot of energy. It can also be converted to hydrogen-based fuels before transportation, but this will again require additional energy. Today, about 85 per cent of the “green” hydrogen that is produced is done so “on-site” so that transportation problems are taken care of.

One of the challenges is the short supply of Electrolyzers. Compared to more established production processes, electrolysis is very expensive, so the market for electrolyzers has been small.

Limitations on use in certain sectors: Hydrogen can be used in various sectors, but there are limitations in certain sectors. The best suited is the industrial sector (mainly steel, ammonia and refineries). Its use in transport and power is restricted since it has to compete with batteries. Hydrogen can be used in heavy duty, long-distance transportation because batteries have low energy-to-weight ratios, and they take a long time to charge compared to fuel cells. For smaller distances, battery-charged vehicles are the most viable option economically. The best use of hydrogen in the power sector is for storage. Hydrogen-based storage is ideal for inter-seasonal storage.

What are the planned policy interventions?

Firstly, the Union government plans to implement the green hydrogen consumption obligation (GHCO) in fertilizer production and petroleum refining, similar to what was done with renewable purchase obligations (RPO). This is expected to start at 10 percent, and increase in later years to 20-25 percent.

Secondly, India plans to shortly kick-start the bids for 4 GW electrolyzer capacity and extending the PLI scheme for manufacturing electrolyzers.

Thirdly, the draft Electricity Rules, 2021, floated by the power ministry have allowed green hydrogen purchases to help meet RPOs.

Fourthly, a range of Indian firms, including NTPC Renewable Energy, have ventured into green hydrogen. The NTPC unit is setting up India’s largest solar park of 4.75 GW in Gujarat and plans to make green hydrogen there on a commercial scale. NTPC has also called bids for setting up a pilot project for mixing green hydrogen with natural gas for the city gas distribution network.

Fifthly, The government is also considering Viability gap funding for green hydrogen in heavy mobility.

What steps can be taken?

Govt can provide policy support: Drastic cost reductions have been visible in solar and wind, and with coherent policy support, there is no reason why this is not possible in the case of hydrogen too.

Development of fuel cell technology: Also, side by side, one has to assume that fuel-cell technology and storage solutions will be developed to a point where hydrogen energy can be used commercially for a variety of purposes.

Competition must be encouraged. Entrepreneurs looking to launch start-ups on this new value chain must be enabled to raise the required funding.

Scale-up green hydrogen: For this, the govt should focus on R&D, ensure access to round-the-clock renewable power for decentralized hydrogen production, and explore blending green hydrogen in existing processes, especially the industrial sector.

We have to make huge investments in research and development to lower the cost of electrolysers and make India a manufacturing hub.

A lot of work will also be required to lay down standards for large-scale use of hydrogen besides framing safety regulations. The recently announced Hydrogen Mission is a step in a right direction.

Conclusion

India has the potential of becoming a hydrogen exporter and should not lose this opportunity as it lost in the case of solar cells and batteries